In the golf equipment industry, the club head is the most complex component—a convergence of material science and aero-mechanical physics. To produce a high-performance club head, a manufacturer must master three pillars: Material Selection, Manufacturing Processes, and Technical Design Specifications.

1. Material Science: The Soul of the Club Head

Different club heads require specific materials to optimize performance and feel:

- Titanium Alloy (Ti 6-4): Primarily used for Driver heads. Due to its high strength-to-weight ratio, Titanium allows for large 460cc heads that remain durable. This material is essential for creating the “spring-like effect” (COR) that maximizes ball speed.

- Stainless Steel (17-4 or 431): The standard for Fairway Woods, Hybrids, and many Irons. 17-4 steel is harder, making it ideal for distance-focused clubs, while 431 steel is softer, offering better feedback and adjustability.

- Soft Carbon Steel (S20C/S25C): The “gold standard” for premium Irons and Wedges. This material is exceptionally soft, providing the “buttery” feel and “stickiness” that elite golfers demand for precision.

- Carbon Fiber: Often integrated into the crown or sole of modern Drivers to shave weight. This allows engineers to redistribute mass to more strategic locations within the head.

2. Manufacturing Methods: Casting vs. Forging

The manufacturing technique dictates the club’s structural integrity and playability:

- Investment Casting: Molten metal is poured into a ceramic mold.

- Advantages: Allows for complex geometry (such as deep Cavity Backs and perimeter weighting) that increases “forgiveness.”

- Market: Cost-effective for mass production and suitable for game-improvement clubs.

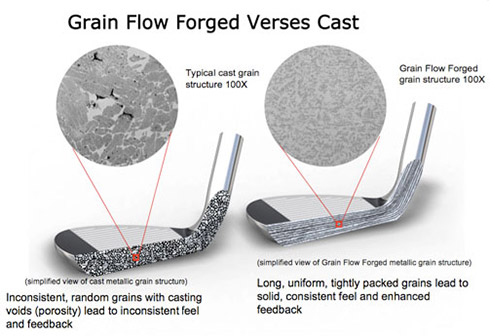

- Forging: A solid block of steel is compressed under extreme pressure into the head’s shape.

- Advantages: Creates a denser, more uniform grain structure, eliminating microscopic air bubbles.

- Feel: Delivers a highly consistent and soft impact sensation, typically preferred by professionals and low-handicappers.

3. Technical Specifications Defining Ball Flight

A precision-engineered head must adhere to strict tolerances in several key areas:

- Loft Angle: Directly controls the launch angle and spin rate.

- Lie Angle: The angle between the center of the shaft and the sole. A deviation of even 1° can cause the ball to start several yards off-target.

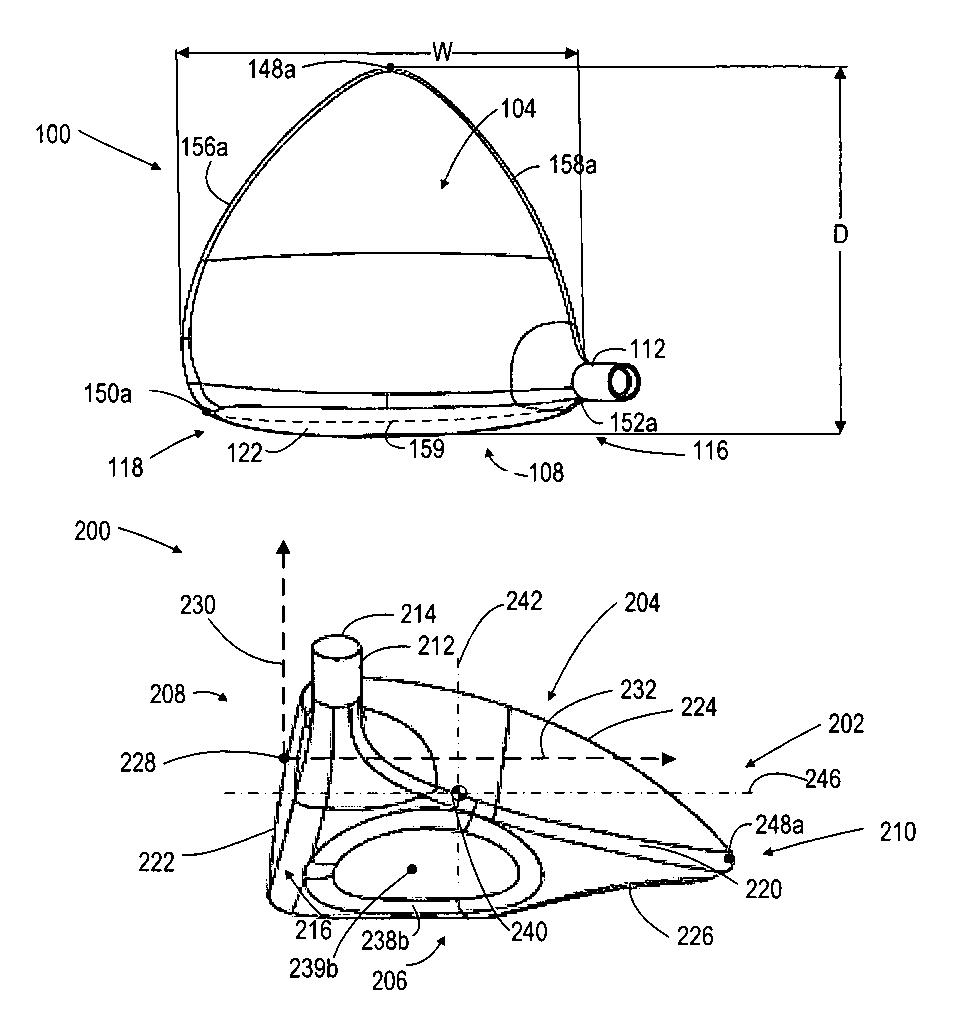

- Center of Gravity (CG): * Low & Deep CG: Promotes a higher launch and increased stability.

- High & Forward CG: Reduces spin and increases ball speed, favored by high-swing-speed players.

- Moment of Inertia (MOI): The head’s resistance to twisting on off-center hits. A higher MOI results in a more “forgiving” club, helping the ball stay on line even when not hit in the “sweet spot.”

4. Face Technology and Precision Milling

The face is the point of impact where energy is transferred. Modern manufacturing focuses on:

- Variable Face Thickness (VFT): Engineering different thicknesses across the face to maintain ball speed on mishits.

- CNC Milling: Using computer-controlled milling to create perfectly sharp grooves. This ensures consistent friction and spin control (spin rate) regardless of turf conditions.

A Note from hansheng precision technology

In our manufacturing facility, a club head is more than just a piece of metal; it is the result of hundreds of hours of CAD simulation and rigorous Quality Control (QC) protocols. We believe that deep technical expertise is the foundation for creating products that help golfers reach their peak performance.

Leave a Reply